Provide flexible solutions and Turn-key

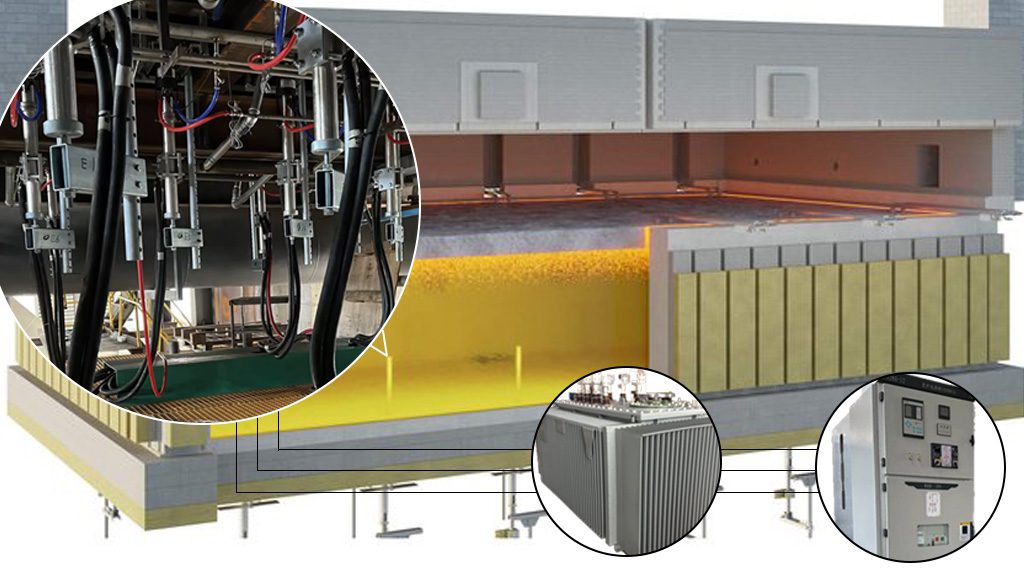

Electric Boosting

Our turn-key electric boosting technology helps to increase furnace output, improved glass quality and reduced emissions with high energy efficiency having our own in-house transformer and power system design and production..

Combustion control skids & burners

Better gas flow control and safety assurance; Pre installation, wiring, and testing before leaving the factory to ensure faster on-site installation; Regulating Gas / Oil Burners; Provides excellent NOx levels and excellent full flame control..

Bubbling System

Generating bubbles at the bottom of the kiln to stir the glass liquid; Effectively reducing energy consumption; Glass liquid is easier to homogenize; Faster color change; Effectively increasing production..

Onsite service

Furnace Glass Draining;Furnace heat-up;

Thermal Regenerator Cleaning;

Furnace feeding, cooling water circulation and rapid cooling;

Feeding after startup;

Full oxygen furnace maintenance..

Melting of non-ferrous metals

Swinging flames greatly reduce the generation of slag;

Full oxygen combustion reduces emissions;

Shorten melting time and improve productivity..

Transformer & Reactor

Multiple cooling methods;Class B, F, H insulation grade;

Single phase, Scott, 3 phase;

Current up to 15kA;

Capacity from 1kVA, up to 12MVA;

Enclosure IP10 ~ IP65..

Permanent magnet transmission

Permanent magnet speed controller and permanent magnet coupler; No connection transmission, flexible start; Maintenance free, adaptable to various harsh working conditions; More efficient energy utilization..

submerged combustion technology

Next generation combustion technology; Ultra high melting rate and excellent homogenize; Start production within two hours and quickly shut down the furnace; Can melt raw materials with high moisture content and low calorific value; Can melt dark black raw materials..